The transport of foodstuffs naturally places special demands on the conveyor systems used. Food must be gentle and hygienic be transported. In the course of transport by means of conveying spirals, it must be possible to exclude contamination and the ingress of foreign substances.

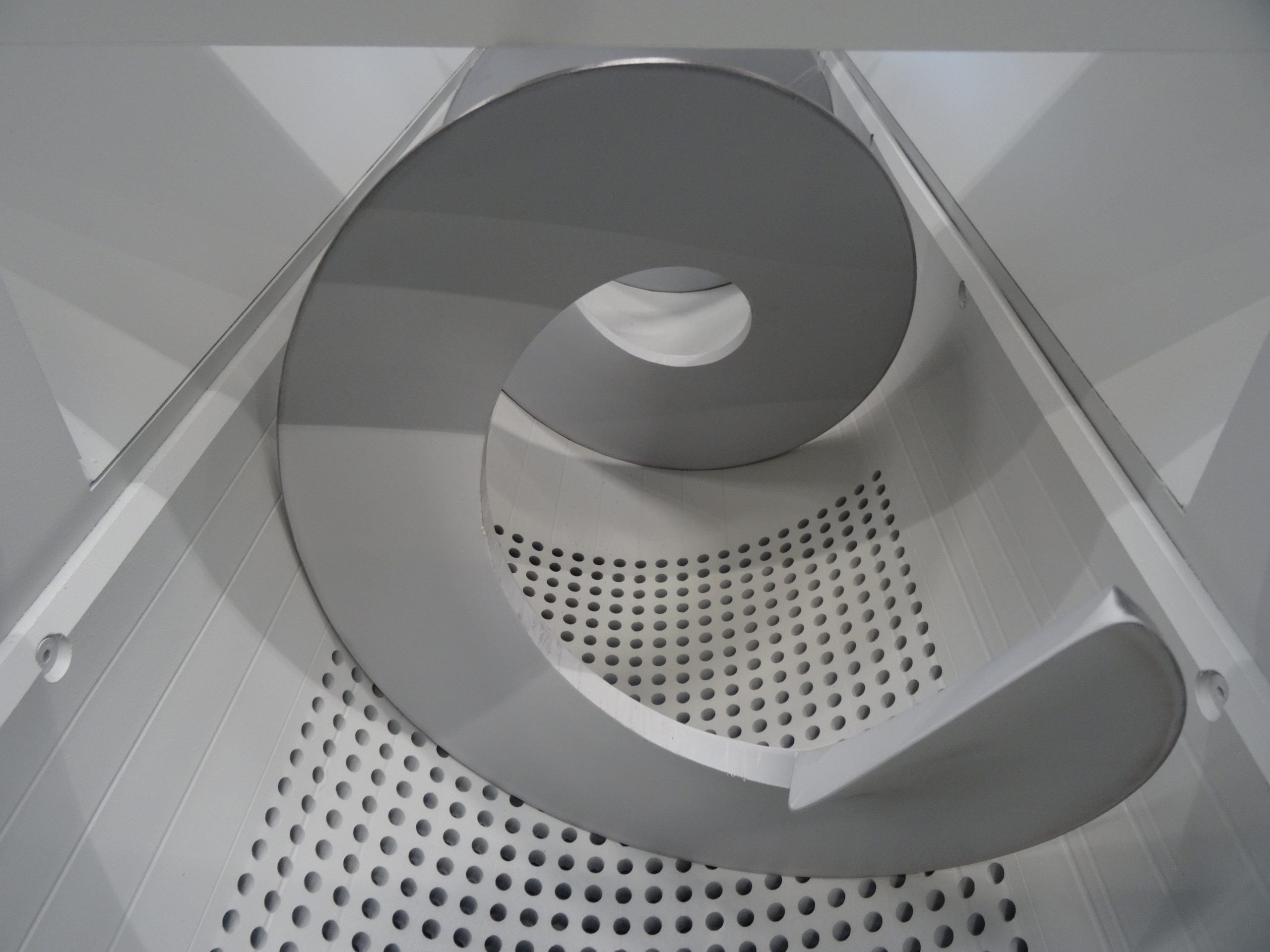

In the course of the promotion of food products come the specific Advantages of shaftless spiral conveyors fromSteiner Spiralen in Kirchdorf.

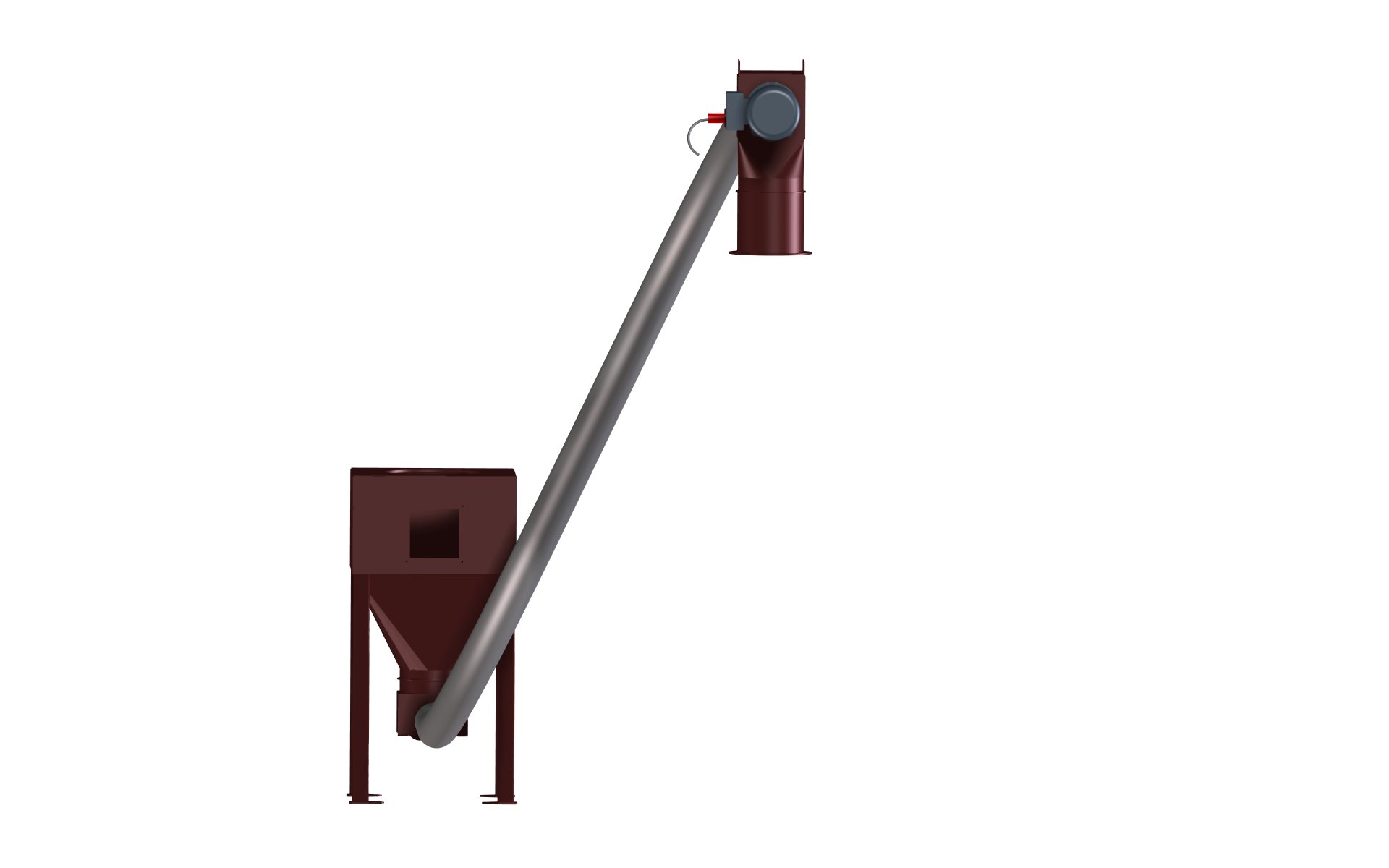

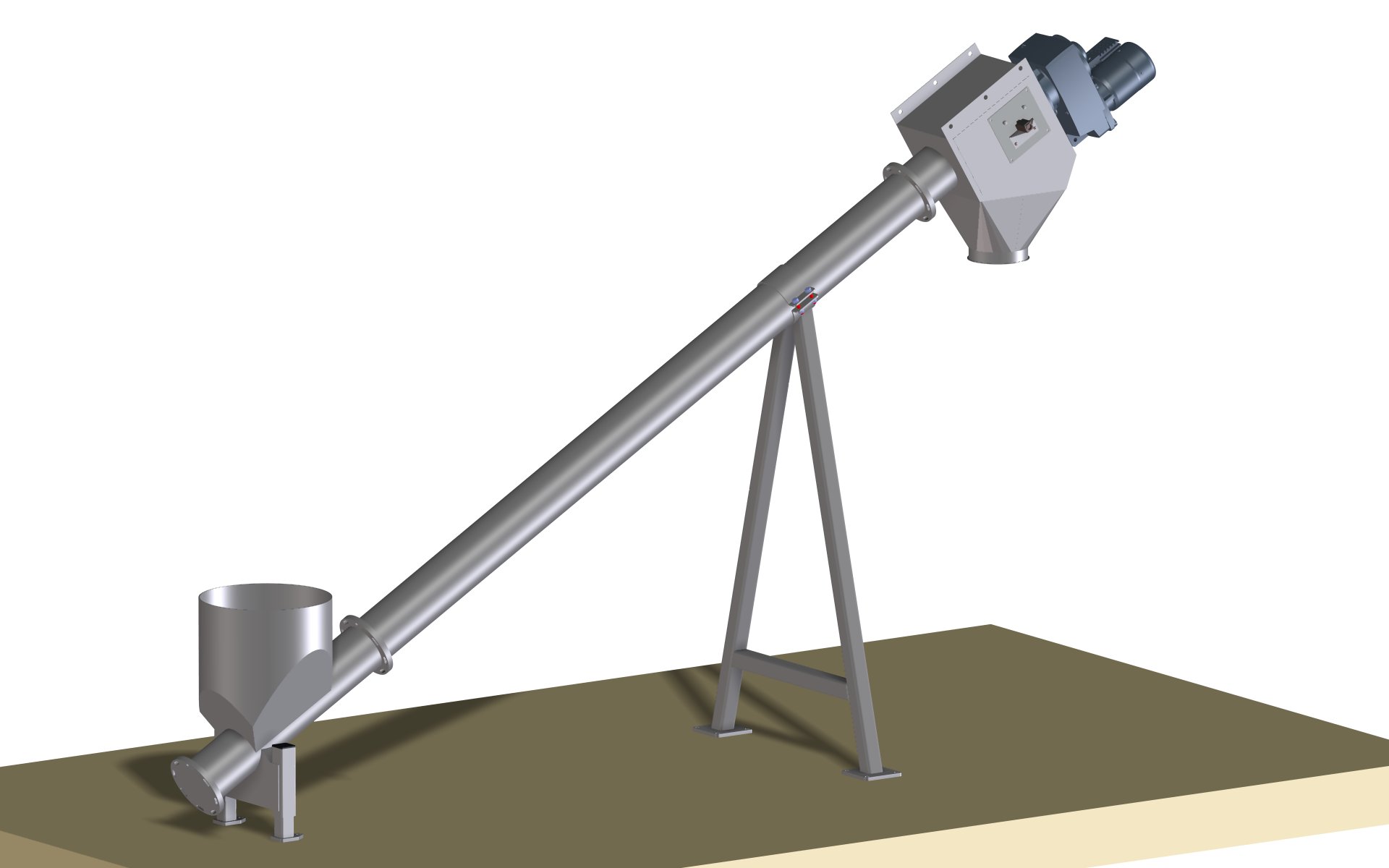

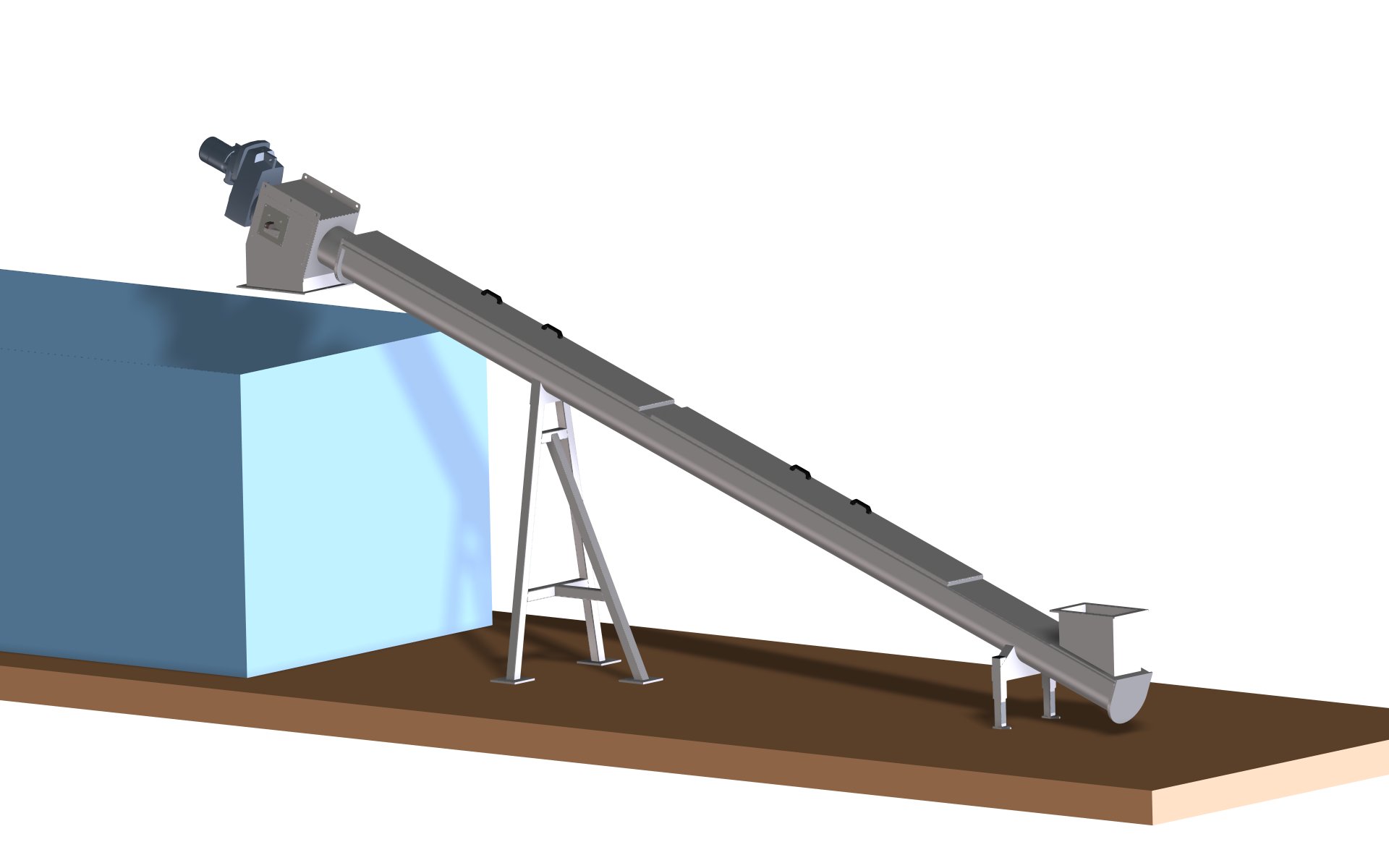

Rigid conveying spirals transport large quantities of material of various sizes. They are also suitable for vertical conveying (vertical conveyors).

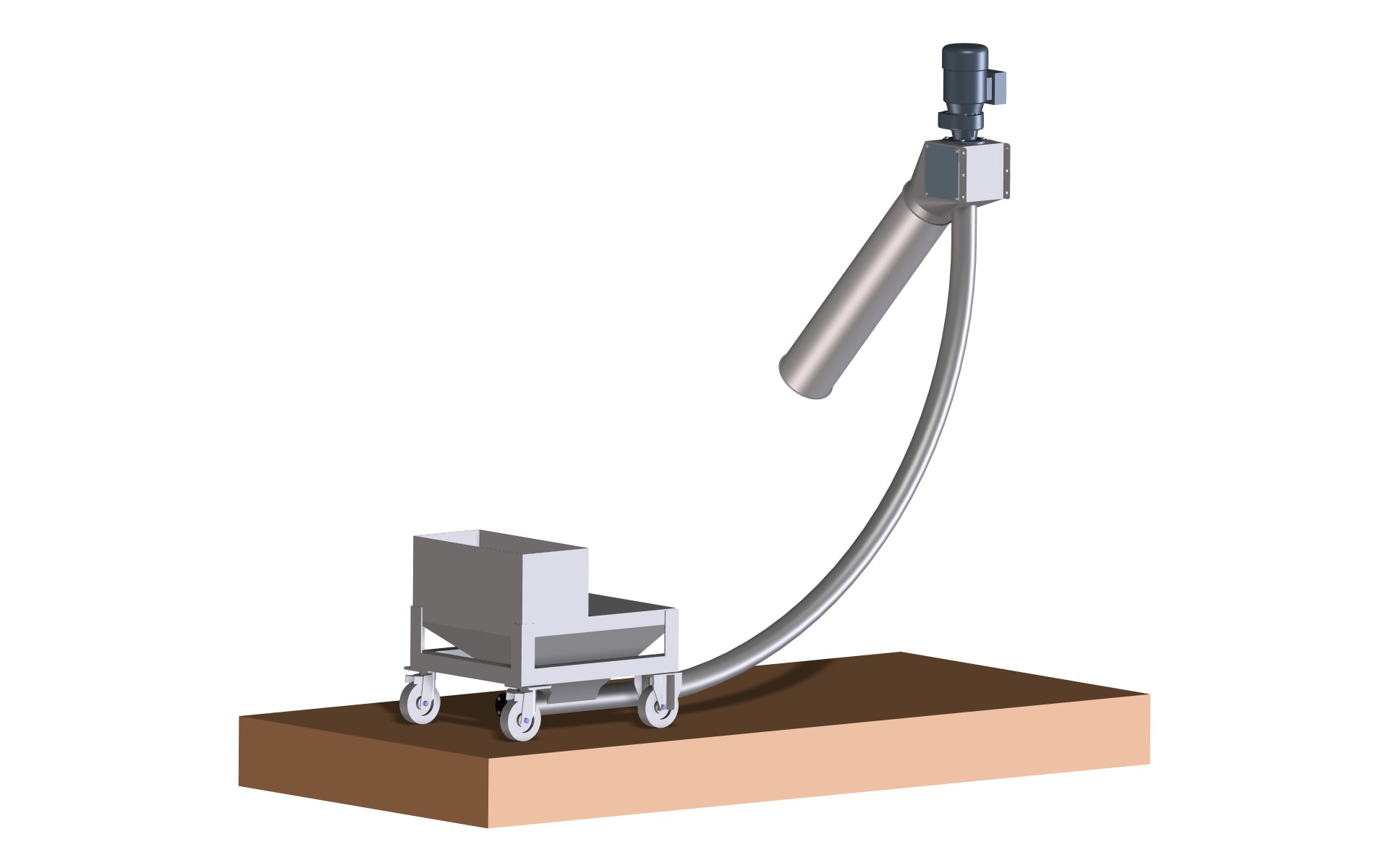

Flexible conveying spirals

made of steel transport food horizontally or vertically even in curves without corners, gears or chains.

Advantages of axisless spirals when transporting food

In addition to these general advantages of

shaftless spirals

The low energy consumption and low maintenance requirements are good reasons for using this conveying technology, especially for foodstuffs:

- Gentle transport of the transported goods. Especially when transporting food, the low conveying speed and the absence of axes, edges and sharp-edged components minimize damage or segregation of the conveyed material

- Dust free / hygienic Promotion. Of course, especially in the case of foodstuffs, there is zero tolerance with regard to contamination of the goods being transported. The closed systems of shaftless conveying spirals ensure this.

- Any consistency – Steiner Spiralen will work with you to develop concepts for conveying materials of widely varying viscosity.

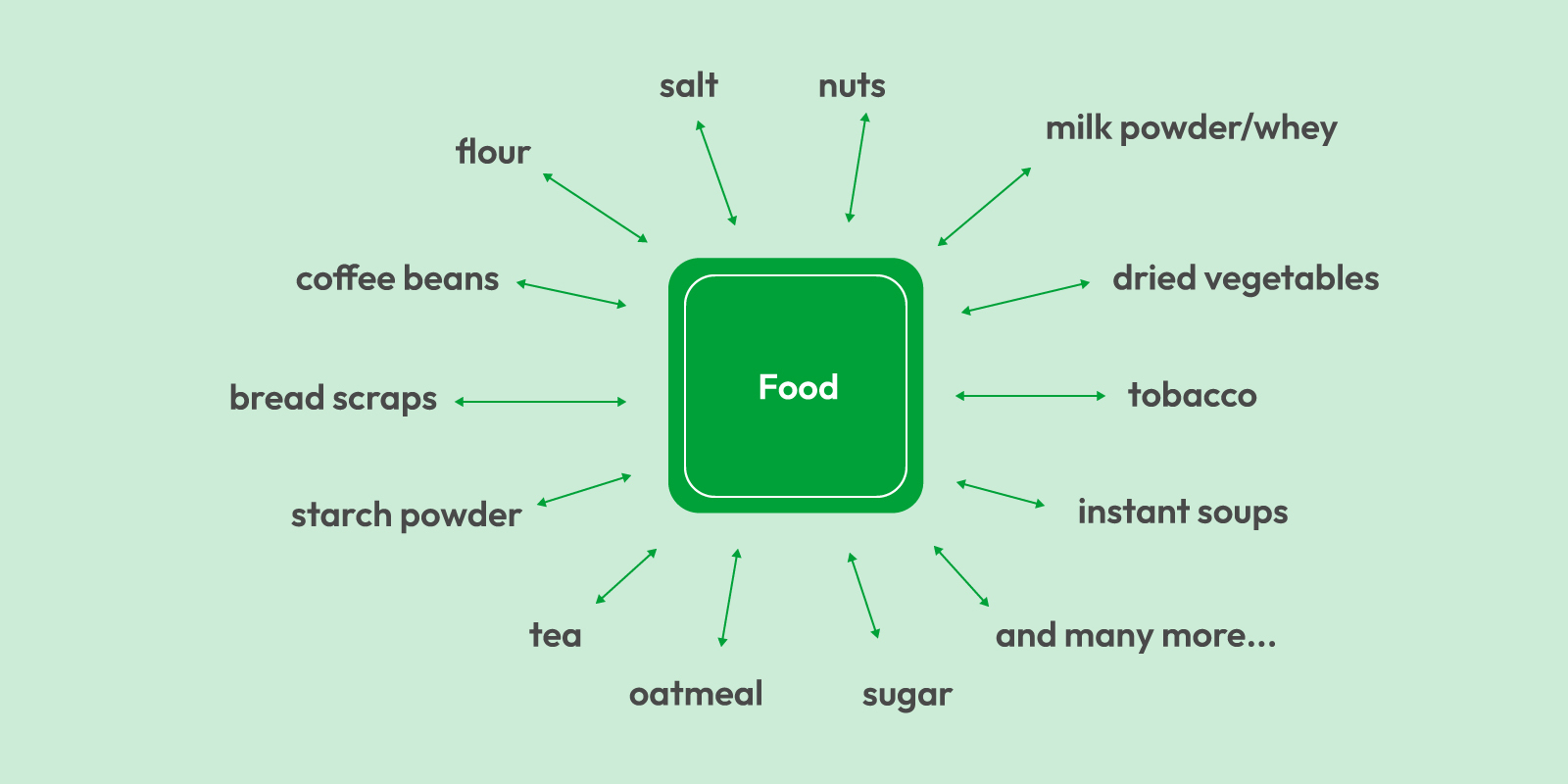

There are hardly any limits to the use of shaftless spirals in the food sector. Due to the precisely fitting and flexible design, almost all types of conveyed goods are conceivable:

- Salt

- Flour

- Coffee beans

- Bread waste

- Starch powder

- Ready-made soups

- Oatmeal

- Flour

- Milk powder, whey powder

- Nuts

- Tobacco

- Tea

- Dried vegetables

- Sugar

- v.m.

The installation of any mechanical or automatic gate valve allows for targeted conveying, dosing and mixing of foodstuffs and for use in silos, filling, packaging or mixing plants.

Steiner Spirals – Tailor-made conveying technology for foodstuffs

Steiner Spiralen from Kirchdorf in Bavaria does not deliver an off-the-shelf product. In accordance with your requirements, the conveying system is developed on a project-specific basis, which optimally meets your requirements in terms of conveying capacity, product protection, maintenance intensity and energy efficiency. Depending on the degree of complexity of the material and the conveying path, conveying tests are often a useful stage on the way to the most target-oriented solution.

Find the customized solution for your processes – Get in touch with Steiner Spiralen!

Solutions