Our conveyor systems

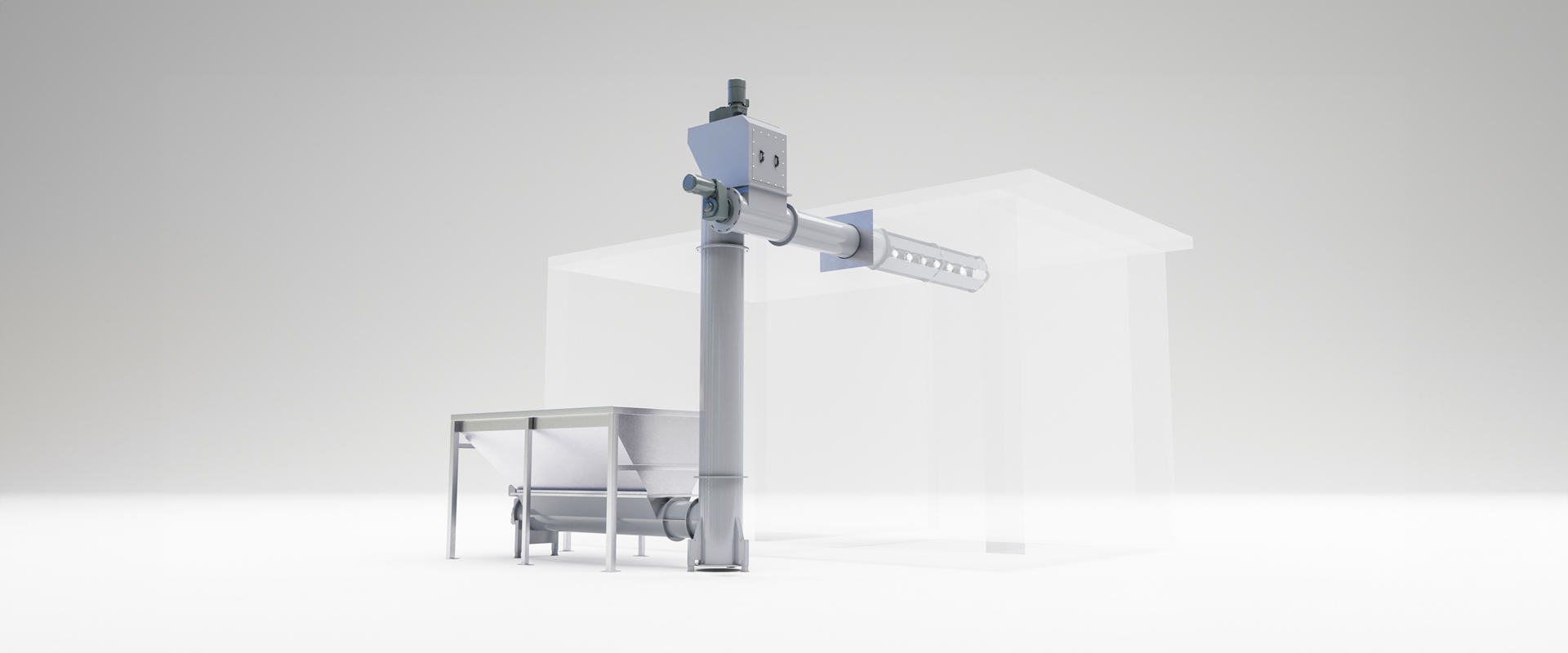

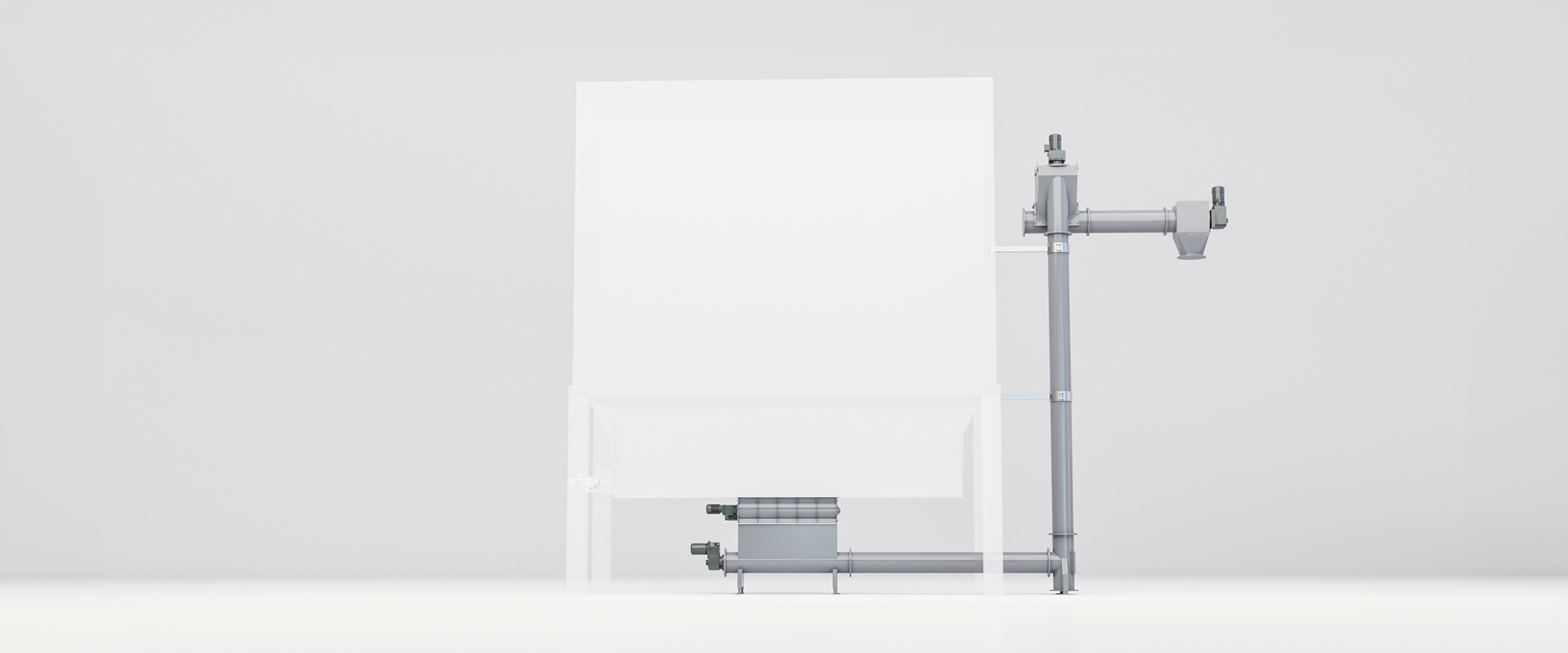

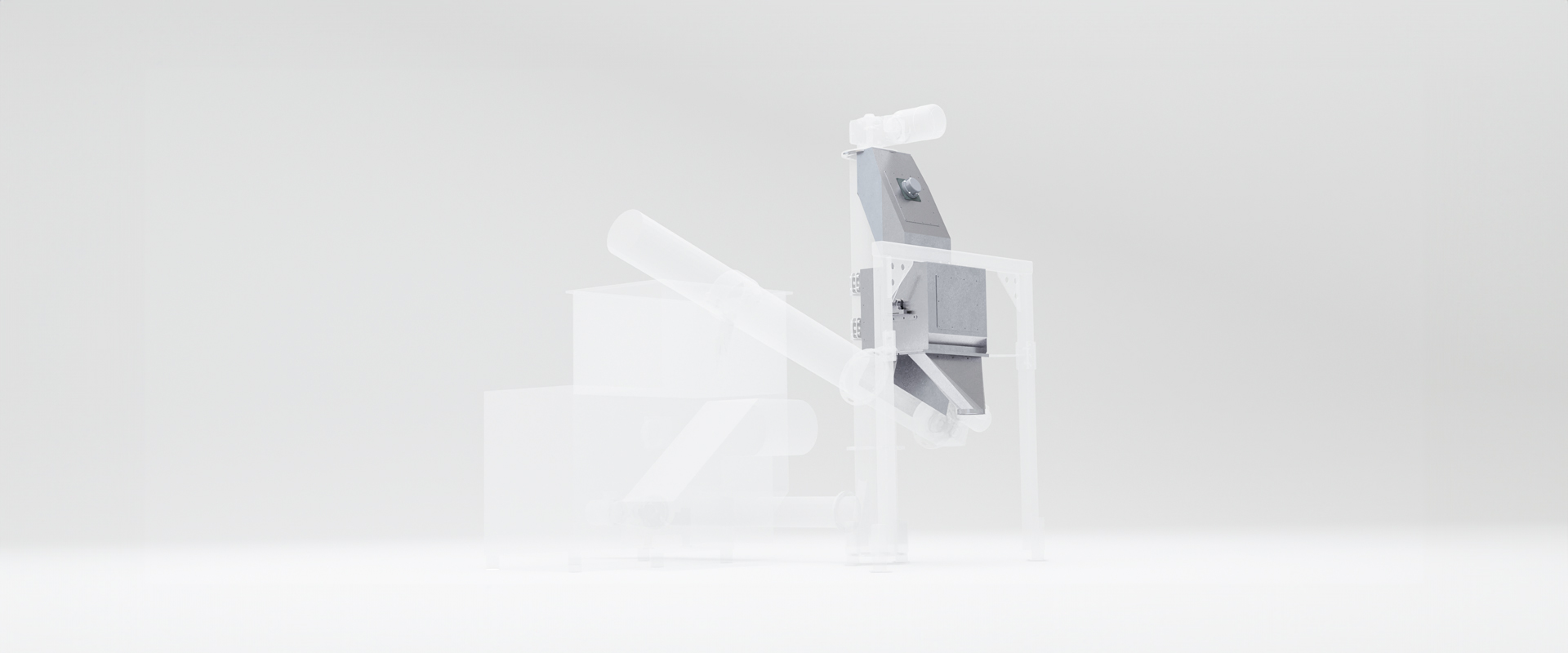

Conveyor systems from Steiner spirals in Kirchdorf, Bavaria, are always individually adapted to your requirements. Depending on the project, we decide together whether conveying spirals or screw conveyors are the most efficient solution for your problem. The material used is also fully aligned with the criteria of your processes.

In the course of the individual project-related planning of your conveyor system, you will find in Steiner spirals from Kirchdorf am Inn a partner for the planning of the entire system. Steiner supports you in developing an overall concept for electrical control, conveyor and weighing technology, installation and commissioning, and also assists you with service and maintenance. If you wish, you can leave the development of the entire concept in our hands. Due to this flexibility, a combination with existing discharge units or machines is also not a problem.

Transporting difficult material, bulk, powder and granules in the most efficient way. Steiner spirals helps you with this. We are very much looking forward to your inquiry!