Steiner GmbH from Kirchdorf am Inn offers the optimal conveyor technology for every material to be conveyed. In the case of abrasive or aggressive materials to be conveyed, the plastic screw conveyor is often the means of choice.

Under the term Archimedean screw, the basic principle of screw conveyors has been in use since ancient times. Due to this simple mechanical principle, screw conveyors require little maintenance and are used very frequently, especially for transporting bulk, granular or powdery material. By means of plastic screws material can be transported horizontally, vertically or with inclination.

Advantages of the screw conveyor

At first glance, the main advantages of the screw conveyor are its high conveying capacity for bulk materials and its resistance to aggressive material properties. However, the advantages of this extraction method are far from being exhausted:

- Low weight

- Energy-saving drive

- Short repair times due to modular technology

- Dry running capability

- Long service life (high durability) due to standard-setting wear resistance

- Easy implementation of product and process change through modular technology

> so the value is maintained and your amortization risk is minimized

- Low friction coefficient

- Simple construction

- Corrosion and chemical resistance

- Good Damping

- Low maintenance

- No environmental pollution

- Physiological harmlessness

- Cheap production

Conveyor technology perfectly adapted to your processes

Conveyor systems from Steiner spirals in Kirchdorf, Bavaria, are always individually adapted to your requirements. Depending on the project, we decide together whether conveying spirals or screw conveyors are the most efficient solution for your problem. The material used is also fully aligned with the criteria of your processes.

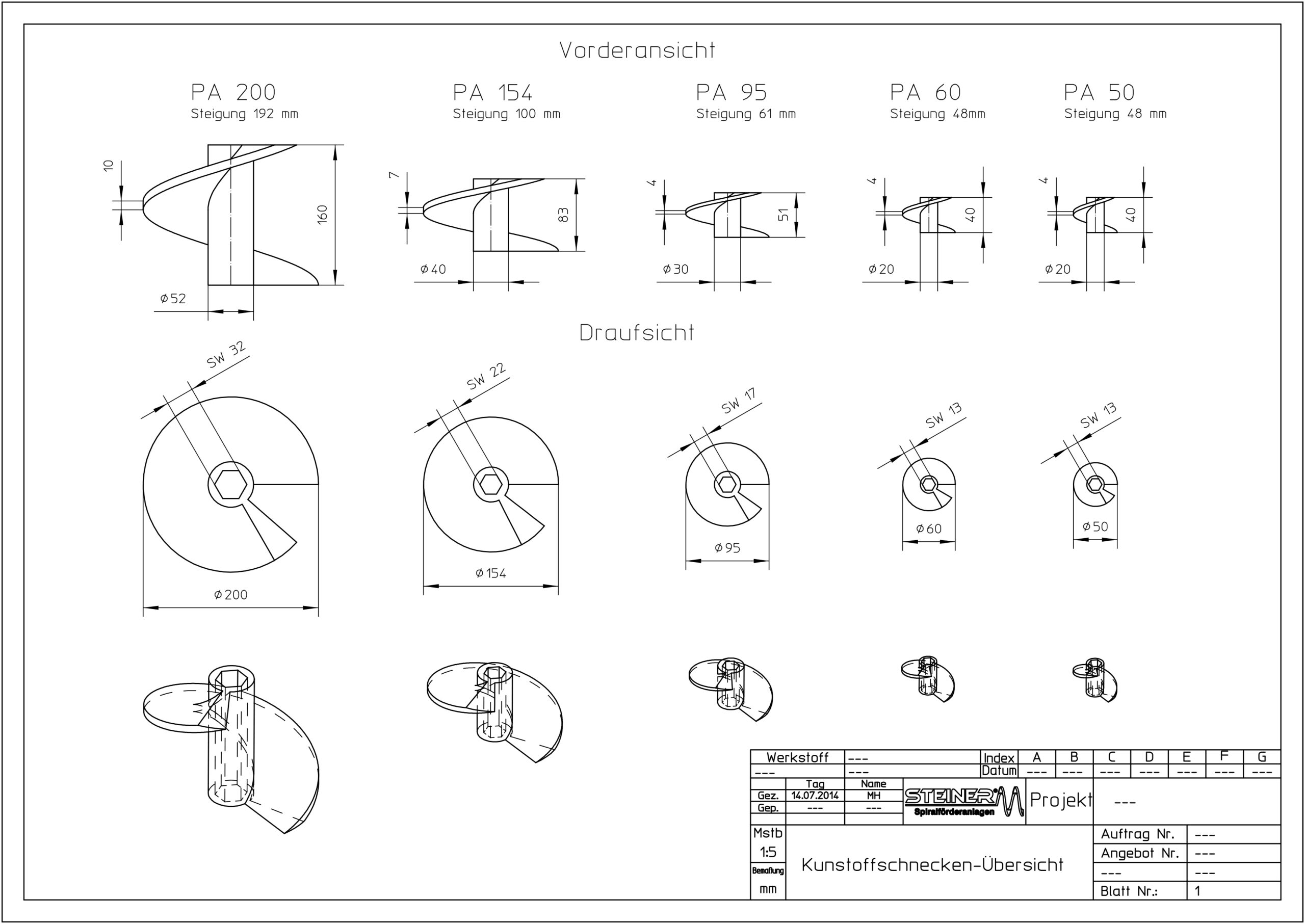

The components of plastic screw conveyors can be customized from the following Plastic compounds are produced:

- PA (standard)

From a purchase quantity of 3,000 pieces

- PE (on request)

- PP (on request)

- PEEK (on request)

- PES (on request)

- SUL (on request)

In the course of the individual project-related planning of your conveyor system, you will find in Steiner spirals from Kirchdorf am Inn a partner for the planning of the entire system. Steiner supports you in developing an overall concept for electrical control, conveyor and weighing technology, installation and commissioning, and also assists you with service and maintenance. If you wish, you can leave the development of the entire concept in our hands. Due to this flexibility, a combination with existing discharge units or machines is also no problem.

Transport difficult material, bulk, powder and granules in the most efficient way. Steiner Spiralen helps you with this. We are very much looking forward to your inquiry!